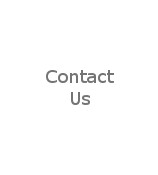

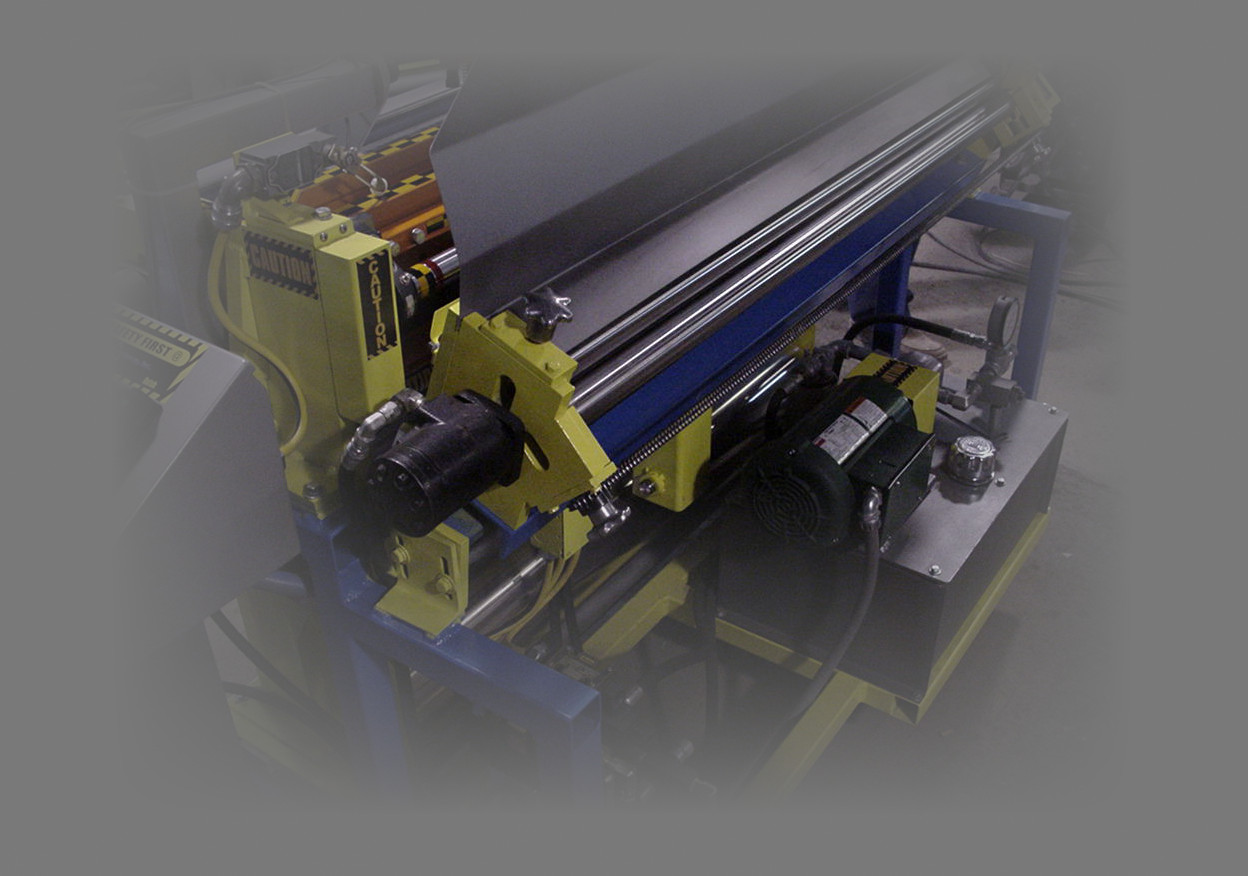

Sheet Metal Cut and Roll Machine

The Harris Precision Cut and Roll Machine is a revolutionary jacket metal machine that contains state of the art features. After plugging the machine into standard power outlets of 110 or 220 volts, the machine is virtually ready to begin cutting and forming jacketing to your specifications. Many various roll stocks can be used including aluminum, stainless steel, and PVC. Comes on casters for easy relocation to your next job site.

Features:

Fully Automatic Operation

Uses Only 16 Sq. Ft. of Working Floor Space

Industrial Casters Standard for Easy Mobility

Feeds Sheet Stock From Below Unit For Easy Handling and Loading

Complete Hydraulic System. No Air Supply Needed.

Adjustable Brass Wear Plates on Shear for Long Life and Dependability

Very Quick Setup Time: Load, Plug In, and Punch In Length and Quantity

State of the Art Digital Controls with Manual Override

Uses Only 16 Sq. Ft. of Working Floor Space

Industrial Casters Standard for Easy Mobility

Feeds Sheet Stock From Below Unit For Easy Handling and Loading

Complete Hydraulic System. No Air Supply Needed.

Adjustable Brass Wear Plates on Shear for Long Life and Dependability

Very Quick Setup Time: Load, Plug In, and Punch In Length and Quantity

State of the Art Digital Controls with Manual Override

Specifications:

Cutting Capacity Thickness Includes the following applications:

.024 Aluminum Sheet or Roll Goods

.016 Stainless Steel Stock

.015 Galvanized Steel Stock

PVC Plastic Stock

Chicken Wire Fencing

Feed Rate Per Minute Approximately 60'

110 or 220 Volts Only Power Source Required, Single Phase or Three Phase(Specify When Ordering)

36" or 50" Wide Stock (Specify When Ordering)

11" Minimum Cut and Roll

Will Cut Flat Sheet Stock With No Roll

Will Accept 100, 200, and 300 Foot Rolls

Approximate Shipping Weight: 1150 Pounds

All Specifications Subject To Change

Comes With One Year Limited Warranty

.024 Aluminum Sheet or Roll Goods

.016 Stainless Steel Stock

.015 Galvanized Steel Stock

PVC Plastic Stock

Chicken Wire Fencing

Feed Rate Per Minute Approximately 60'

110 or 220 Volts Only Power Source Required, Single Phase or Three Phase(Specify When Ordering)

36" or 50" Wide Stock (Specify When Ordering)

11" Minimum Cut and Roll

Will Cut Flat Sheet Stock With No Roll

Will Accept 100, 200, and 300 Foot Rolls

Approximate Shipping Weight: 1150 Pounds

All Specifications Subject To Change

Comes With One Year Limited Warranty

Available Options:

Single Roll Adjustment

Front Roll Off Table

2 Position Carriage Roll Stand with Pass Line Roll

5/8" Hug Edge Brake

Heavy Duty .032 Aluminum Cutting Capacity with Panel Flat Straightener

Front Roll Off Table

2 Position Carriage Roll Stand with Pass Line Roll

5/8" Hug Edge Brake

Heavy Duty .032 Aluminum Cutting Capacity with Panel Flat Straightener

"a total system of performance"